3D printing: A Sustainable Innovation

At FormFutura we firmly believe that environmental harmony is vital for the well-being of current and future generations. Therefore, we are reshaping the world of 3D printing by emphasizing sustainability and actively pursuing an eco-friendly future. This is not just a commitment; it's a journey we embark on every day.

3D printing itself is inherently sustainable, contributing to the reduction of waste through a process known as fused filament fabrication (FFF). Unlike traditional mass fabrication methods that involve carving or stamping objects from larger materials, FFF enables desktop 3D printers to construct objects layer by layer, minimizing material wastage.

Our sustainability initiatives

As the additive manufacturing industry continues to grow, FormFutura remains steadfast in its commitment to reduce its environmental impact. To fulfil this commitment, we have implemented a range of sustainable practices designed to minimize our environmental footprint. Explore our dedication, delve into our initiatives, and join us in creating a positive impact on the environment, the industry, and beyond. Together, we are building a world where sustainable 3D printing isn't just a goal but a reality.

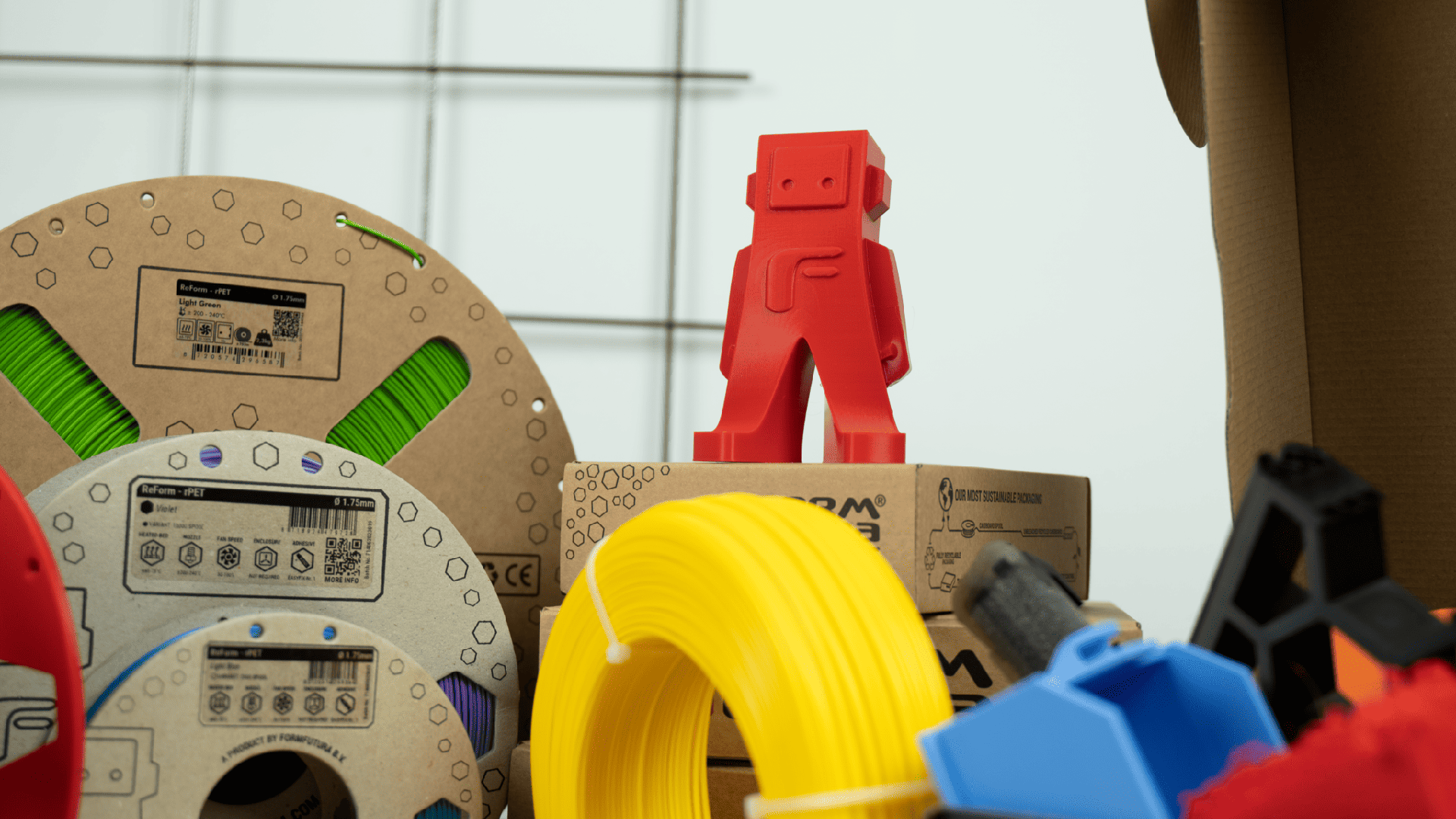

Reform Filaments

In 2021, we proudly introduced the Reform Filament, representing one of the most sustainable filament ranges in the market. Our commitment to environmental responsibility is evident in every aspect of this filament.Crafted entirely from renewable materials, the Reform Filament breaks away from the reliance on virgin fossil or natural resources. We go beyond traditional practices, offering recycled variants of PLA, PET(G), ABS, and ASA, ensuring that all waste streams from production find purpose. To further reduce our environmental footprint, the Reform Filament is presented on eco-friendly cardboard spools, available in five sizes, ranging up to 4.5 kg.

PLA Filaments

PLA is one of the leading materials in desktop 3D printing. This thermoplastic is made from plant starch, such as corn, cassava, sugarcane, cereals, or sugar beet.Therefore, it is biodegradable under suitable conditions, offering a more environmentally friendly option compared to fossil fuel-based alternatives. While ABS and PLA have distinct characteristics, such as strength and melting temperatures, choosing between them depends on your specific 3D printing project needs. PLA, being eco-friendly, is often favored by those prioritizing sustainability in their initiatives.

Why is 3D Printing Sustainable?

Reducing Carbon Emissions

Desktop 3D printers use digital CAD files to produce physical items exactly where needed, potentially reducing emissions linked to global transport. They create diverse objects within printer limits, removing the need for unique machinery per product and improving resource efficiency.

Repairing & Upcycling

Desktop 3D printing enables the repair of household items by producing parts no longer sold by manufacturers. This extends product life and prevents waste. It also allows for creative upcycling—adding new features or purposes to existing objects—offering a sustainable way to reuse what we already have.

Partnerships for a Better Future

We support the UN’s 2030 goals by using 3D printing to improve lives. Partnering with various companies, we help create low-cost assistive tools and custom medical devices—like implants and prosthetics—tailored to each person's needs.

Recycling Program

Through our recycling program, you can say goodbye to failed prints and excess materials, all without incurring any costs. We breathe new life into old products, turning them into high-quality filaments, all while significantly reducing waste.

Refill Filaments

Our Refill filaments come without a spool and are designed to fit our FormFutura flanges. You can even create your own custom-made flanges. The filament is packaged on a coil and stored in reusable vacuum-sealed zip bags, minimizing packaging waste, improving shipping efficiency, and reducing environmental impact.

Eco-Friendly Packaging

In 2020, we implemented a significant change by transitioning to cardboard spools for all our filament variants. This shift ensures that all FormFutura filaments up to 1 kilogram are spooled onto fully recyclable, sturdy cardboard spools crafted from unbleached recycled cardboard. This eco-friendly approach extends beyond the spools to also include the boxes that the spools comes in. Our decision had a positive influence on numerous other 3D printing brands. We were very pleased to see many brands following our lead in providing spools on cardboard, contributing to a more sustainable industry standard.